Chrome paint and other different techniques to obtain chrome effects

When considering chrome spray paint alternatives, it’s essential to recognize that other processes and paints are aluminum or silver-based and free from carcinogenic elements like Chromium VI. This means there are safe chemical and painting techniques available.

Chrome spray paints come in two main forms, each with its unique characteristics and application methods. Neither type functions like conventional paint, as they’re composed of flat, precisely shaped aluminum micro-particles designed to reflect light like a mirror.

Professional-grade chrome paint works through evaporation. The process involves applying an ultra-shiny, hard undercoat using a spray gun, airbrush, or aerosol. This undercoat evaporates at a rate of 99%, leaving behind a thin silver film. A subsequent varnish application provides resistance to liquids, abrasion, and UV exposure, making it suitable for both indoor and outdoor use.

The second type is often referred to as ‘leafing’ paint, designed specifically for artistic and creative applications. This simplified version of chrome spray paint requires only a single coat and can be applied using a brush, spray, airbrush, or spray gun. Its ease of application makes it an attractive option for those looking to add a touch of chrome to their projects.

Which Simple And Accessible Chrome Plating Technique To Choose?

Before attempting to chrome an object, it’s essential to consider several factors. When deciding on the best approach, ask yourself: Are you equipped with a specific toolset, such as airbrushes or spray guns? Are you willing to employ intricate multi-coating techniques, which can be time-consuming and require precision? Moreover, think about the object’s intended environment. Will it be exposed to abrasion, water, or human touch, or will it remain stationary and out of reach? Answering these questions will help you determine the most effective solution for achieving a satisfactory chrome finish.

What Can Be Chromed, And With What Technique?

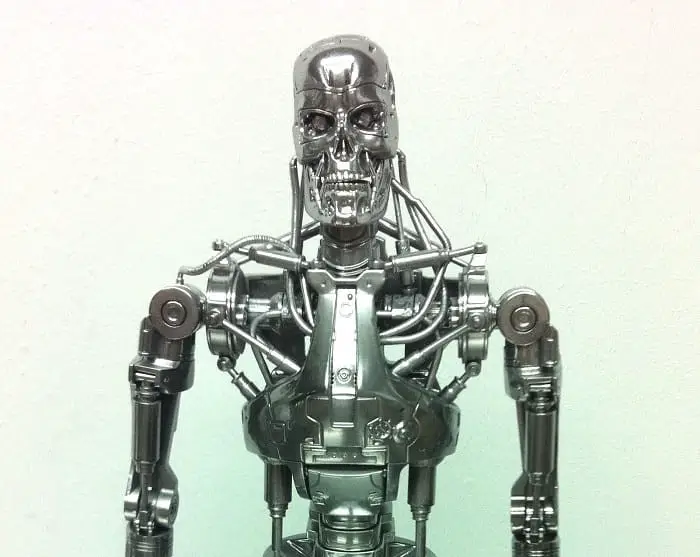

When it comes to enhancing the visual appeal of various items, two popular options are headlight optics with chrome or silver plating, and professional-grade chrome painting for applications such as chair frames and shower fixtures. For vehicles like bicycles, bumpers, and rims, professional-grade chrome paint is often used to achieve a high-gloss finish. In other cases, such as decorative items like chandeliers, trinkets, statues, and trophies, various types of paint can be employed to achieve the desired look. Additionally, for model making purposes, both silver plating and paints can be utilized to create realistic and visually appealing results.

On Which Surfaces Can Chrome Paint Be Applied?

One of the most significant advantages of paints is their ease of use. What’s more, regardless of the size or shape of the object, as well as its material, it’s always possible to apply paint to it, provided we’ve properly prepared the surface beforehand. This versatility extends to a wide range of materials, including plaster, leather, wood, and concrete, as long as we take the necessary steps to clean, sand, dust, and prime the surface.

Chrome Spray Paint: What Is It Worth?

When it comes to purchasing a cap, don’t be fooled by its appearance if it’s from a supermarket or non-specialized store. The chrome-plated cap is likely a clever disguise for a simpler, metallic-painted product that lacks the genuine mirror-like finish.

The Most Convenient To Achieve…

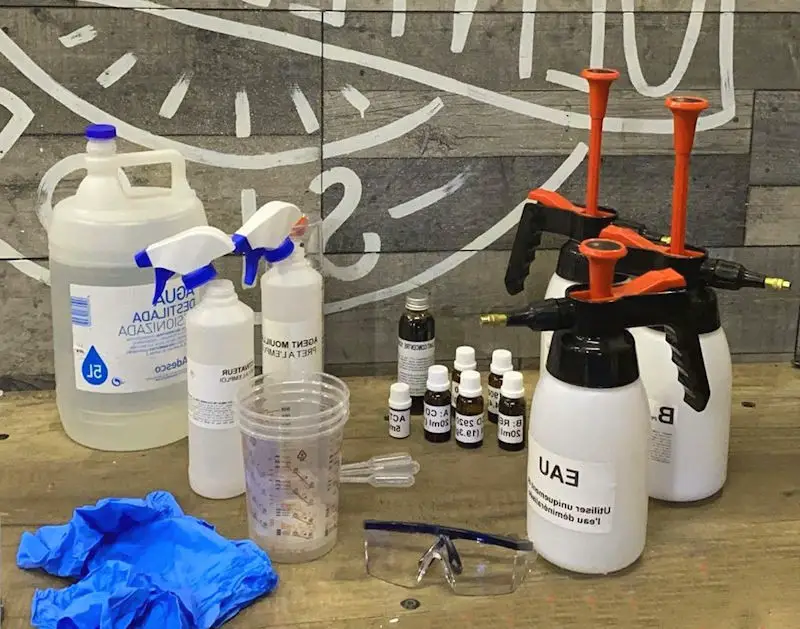

This extraordinary paint, dubbed ‘floating chrome’, has the remarkable ability to transform any surface into a mirror-like finish in mere seconds after application. Regardless of the surface type or condition, it effortlessly produces a reflective, chrome-like sheen. However, its Achilles’ heel lies in its susceptibility to handling and light touch, yet it remains resistant to rubbing or weather exposure. Furthermore, it cannot be varnished.The silvering process is undoubtedly the crowning glory of this paint, resulting in an unparalleled liquid mirror that shines like polished chrome itself. The good news is that even non-professionals can attempt the silvering reaction with a mini chemistry kit designed specifically for chrome silvering. This kit is capable of handling objects up to 30 cm in size.The products are supplied as aerosol undercoats and varnishes, along with small vials of concentrated chemicals that require dilution with distilled water and application using pump sprayers.

Professional Plating Techniques To Obtain Chrome-free Chrome Plating

The world of chemical techniques is vast, and among its many wonders are methods that yield exceptional mirror effects. PVD chrome, Sputtering, and silvering are three such techniques that have garnered attention for their ability to produce high-quality mirrors. Sputtering, also known as vacuum chromium plating, employs an electrical process to deposit a thin layer of aluminum pigments onto a hard, shiny surface – much like the process used with chrome paint. This method is well-suited for interior elements such as windows, furniture, and decorations, as well as exterior architectural features that are exposed to sunlight.In addition to its application in mirrors, Sputtering has also been used to create luxurious statues, car headlights, and perfume bottles. Another notable technique is silver plating, which has been a staple of chemistry courses for over 100 years. This reaction utilizes the precious metal silver (Ag) for its exceptional qualities, including its perfection, fineness, and ability to produce a mirror when deposited in a few nanometers or micrometers onto a shiny coating. The process involves the reduction of silver nitrate solution on an activated tin chloride background, with the resulting products being sprayed or poured.While the silver mirror technique is renowned for its exceptional results, it does come with some limitations and drawbacks. Implementing this technique can be challenging, and silver itself has a tendency to degrade when exposed to sunlight and UV rays – it gradually turns yellow over time. However, this issue can be mitigated by applying a clearcoat to the finished product, effectively creating a gold bullion effect.

Achieving Colored Chromes

With modern painting and silvering techniques, it’s surprisingly simple to create an endless array of colors on chrome surfaces. This can be achieved by applying a clearcoat infused with yellow ink. The resulting palette boasts an impressive twenty or so transparent inks, allowing for virtually unlimited coloring options. For those seeking further insight into the world of chrome, a visit to Wikipedia’s article on the subject is highly recommended.